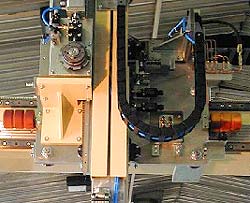

The infeed gantry is mostly used for insertion of workpieces into machine tools. It consists of pedestal, horizontal axis, traversing carriage, vertical axis and clamping head.

The pedestal is made of thick-walled steel profiles and can be manufactured with two or three legs. The three legs are suitable, if a great stability is required, or for a reason of an insufficient space, e.g. to keep the access to machine free or to retain the possibility of machine cover removal.